As with our conventional exterior gears, shaft options include flat or hex shafts, and we use gear cutting strategies from broaching to hobbing, depending on design options and end-user requirements. We are able to also heat treat inner gears via carburizing, flame induction, or nitriding.

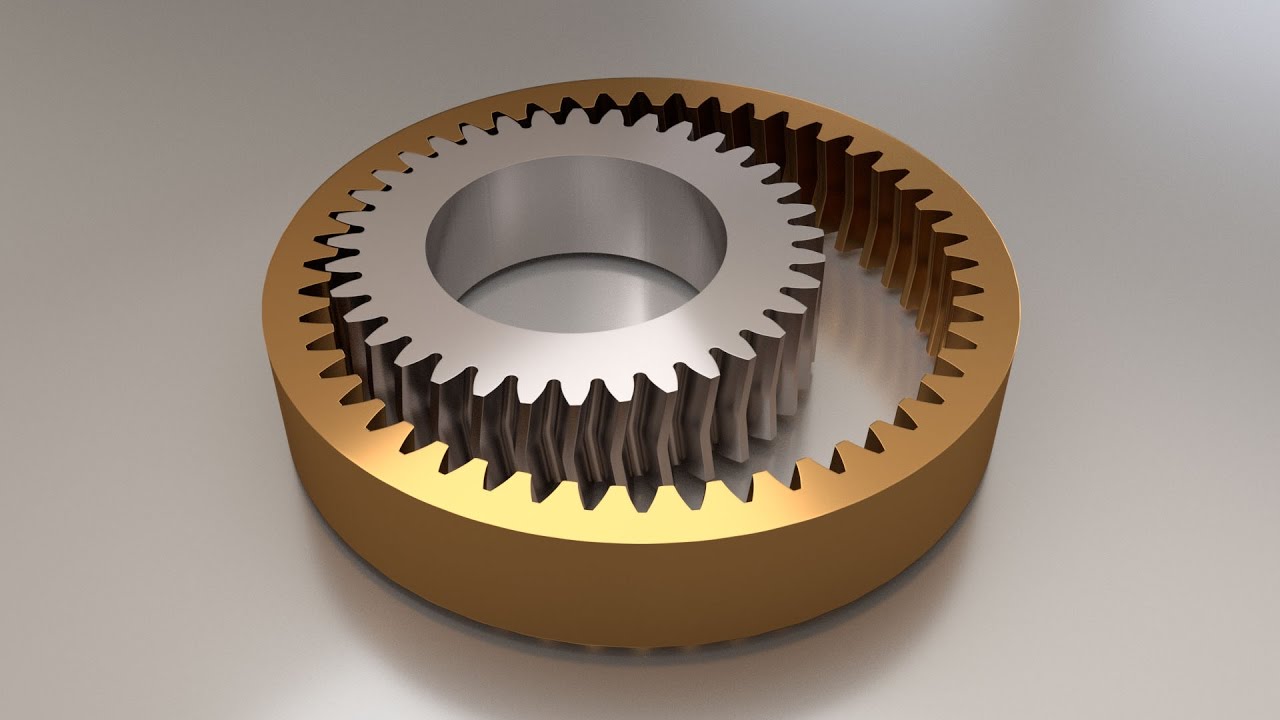

Ever-Power full type of gear manufacturing services includes internal gears, in addition to our collection of conventional, external gears. Internal gears, with teeth located on the inside as opposed to the outside of the gear, are found in all sectors, from military/government to electronics and chemical applications. We also provide clients in the medical, auto, biotechnology, and packaging industrial sectors. Our internal gears could  be stated in diameters up to 42″, with a maximum diametrical pitch of 2.5, and a maximum module of 10.

be stated in diameters up to 42″, with a maximum diametrical pitch of 2.5, and a maximum module of 10.

Custom Internal Gears

We substantiate our quality for you on every equipment we manufacture by e-mail through the modern On-plank Inspection and Software Technology available anywhere in the world.

Decreased sliding action because of internal gear tooth configuration

Decreased sliding means less friction and less tooth wear

Internal gear in a few applications eliminates dependence on an idler gear

Internal gears may be operated in a fixed position or a free rotating with pinion fixed

Ever-Power internal gear grinding technology “exceeds that of any of our competitors” and we can manufacture the biggest Pinions of any Pitch and Encounter Widths as high as 80″. This technology also gives us Inspection Capabilities for Lead, Pitch, Profile, & Runout, on Internal Gears up to 240″ Diameter. The precision design and produce of our inner gears outcomes in smoother procedure and better performance.